- Home

- About us

- Products

- Faqs

- Titanium material using application areas

- Immersion anode(Ti/Cu,Zr/Cu,Stainless steel /Cu...) advantages

- The performance of stainless steel

- The performance of Titanium

- Titanium Screws & Nuts

- The performance of the non-ferrous metals nickel, tantalum, niobium and uses

- Application of Titanium Cathode Plate in electrolytic and hydrometallurgical industry.

- Titanium Seamless Tube

- News

- Certificate

- Contact us

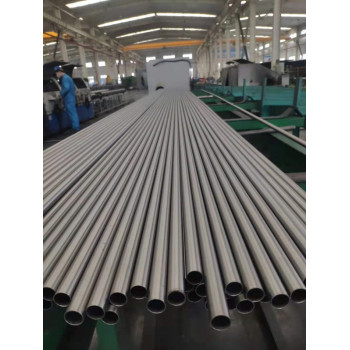

Titanium seamless tube

- group name

- Titanium, Zirconium, and Nickel Alloy Tubes & Pipes

- Min Order

- 1 piece

- brand name

- Special Steel Titanium Industry

- model

- Dia15.88*0.89mmT*6000mmL

- Nearest port for product export

- Shanghai, Tianjin, Beijing, Xi'An

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C

- update time

- Sat, 31 Jan 2026 06:13:48 GMT

Paramtents

ASTMB 338 GR1

titanium alloy has low density high specific strength

good corrosion resistance low thermal conductivity

non-toxic, non-magnetic, solderable, good biocompatibility

Packging & Delivery

-

Min Order1 piece

Briefing

Detailed

Titanium alloy has low density, high specific strength, excellent corrosion resistance, low thermal conductivity, is non-toxic, non-magnetic, solderable, and has good biocompatibility and a strong decorative surface.

Applications: Widely used in heat exchange equipment such as tube heat exchangers, coil heat exchangers, snake tube heat exchangers, condensers, evaporators, and conveying pipes. Titanium tubes are also the standard tubes used in many nuclear power industries.

Standards: According to user requirements, titanium tubes are produced following national standards GB/T 3624-2010, GB/T 3625-2007 and ASTM 337/338.

Titanium Seamless Tube

Advantages and Applications

Specifications

Cold Rolled / Cold Drawn Seamless Tubes

Outer Diameter (mm)

Available Wall Thickness (mm)

10 – 15 0.5, 0.6, 0.8, 1.0, 1.25, 1.5, 2.0 >15 – 20 0.6, 0.8, 1.0, 1.25, 1.5, 2.0, 2.5 >20 – 30 0.6, 0.8, 1.0, 1.25, 1.5, 2.0, 2.5 >30 – 40 1.0, 1.25, 1.5, 2.0, 2.5 >40 – 50 1.5, 2.0, 2.5, 3.0 >50 – 60 1.5, 2.0, 2.5, 3.0, 3.5 >60 – 80 2.0, 2.5, 3.0, 3.5, 4.0, 4.5 Welded Tubes

Outer Diameter (mm)

Available Wall Thickness (mm)

16 0.5, 0.6, 0.8, 1.0 19 0.5, 0.6, 0.8, 1.0, 1.25 25, 27 0.5, 0.6, 0.8, 1.0, 1.25, 1.5 31, 32, 33 0.8, 1.0, 1.25, 1.5, 2.0 38 1.5, 2.0, 2.5 50 2.0, 2.5 63 2.0, 2.5 Welded-Rolled Tubes

Outer Diameter (mm)

Available Wall Thickness (mm)

6 – 10 0.5, 0.6, 0.8, 1.0, 1.25 >10 – 15 0.5, 0.6, 0.8, 1.0, 1.25, 1.5 >15 – 20 0.5, 0.6, 0.8, 1.0, 1.25, 1.5, 2.0 >20 – 25 0.5, 0.6, 0.8, 1.0, 1.25, 1.5, 2.0 >25 – 30 0.5, 0.6, 0.8, 1.0, 1.25, 1.5, 2.0 Available Grades & Processing Methods

Grade

Supply Condition

Manufacturing Method

TA1 Annealed (M) Cold Rolled / Cold Drawn TA2 Annealed (M) Cold Rolled / Cold Drawn TA9 Annealed (M) Cold Rolled / Cold Drawn TA10 Annealed (M) Cold Rolled / Cold Drawn